*

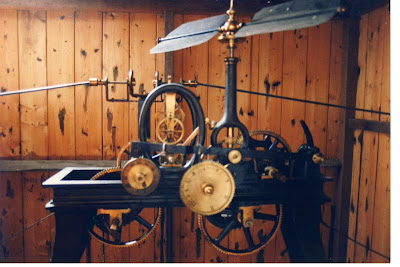

Large slave clock movements were used when a medium-large clock dial was given a glass cover or was installed in a protected [indoor] environment. Perhaps within a railway station, a large office foyer or factory building. One large dial allowed the time to be read at a great distance. This saved the expense of many small dials and the greater risk of timekeeping scattering between them. Glass covered dials only worked well when the sky could not be reflected.

Large slave clock movements were used when a medium-large clock dial was given a glass cover or was installed in a protected [indoor] environment. Perhaps within a railway station, a large office foyer or factory building. One large dial allowed the time to be read at a great distance. This saved the expense of many small dials and the greater risk of timekeeping scattering between them. Glass covered dials only worked well when the sky could not be reflected.

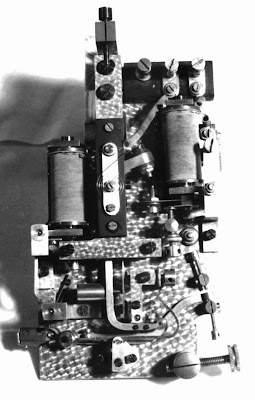

A general view of the large slave movement. The maximum dimensions of the flanges on its white protective box are approximately 10" high x 8" wide. [25 x 20cm] The overall protective metal plating and paper covered coil indicate a later movement.

A slave movement was a far cheaper and simpler option than installing a weight driven turret clock or electro-magnetic Waiting Train movement. Being so compact, the large slave could be installed where nothing else would fit. Being highly reliable, it could be installed where maintenance access was very poor. Considerable effort was expended in making these large slave movements robust and well protected against deterioration due to weather, wear or condensation.

These turret slave mechanisms, like their much smaller brethren, are really spring driven. Except that the spring is briefly tensioned only at each half minute by the large electromagnet. Once the brief electromagnet impulse ends, the magnetic circuit collapses and the spring pulls the hands around the dial in a single, half minute step. The electrical impulse was provided by an accurate master clock controlling a complete impulse timekeeping system. The large slave would usually be placed in electrical series with the rest of the many smaller dials and any other equipment in the time circuit. Though its relatively high resistance usually required a serious step-up in DC voltage to the system. Since this involved considerably greater expense, in the days of battery bank driven time systems, the slave dial might have been controlled by a relay and its own, separate power supply.

This image shows a closer view of the coil spring which drives the hands at half minute intervals. The spring's tension can be adjusted with the screwed rod on its left. Though here it is at its most relaxed position.

The various silver-coloured levers look rather complex but simply drive the ratchet wheel forward and prevent its backward movement. By the skilful design of these levers, the hands of the clock are prevented from ever moving too far at each step or falling back. Either of which would ruin the timekeeping.

Here is an even closer, labelled, view showing the coiled drive spring just above the double-locked, backstop lever. The long horizontal lever has a downward extending pawl which sits in the teeth of the drive wheel. This pawl stops the wheel from ever turning backwards. It is hinged on the left so that it can rise or fall slightly to allow only one tooth to pass at each electrical impulse.

Here is an even closer, labelled, view showing the coiled drive spring just above the double-locked, backstop lever. The long horizontal lever has a downward extending pawl which sits in the teeth of the drive wheel. This pawl stops the wheel from ever turning backwards. It is hinged on the left so that it can rise or fall slightly to allow only one tooth to pass at each electrical impulse.On the right of the long lever is a reinforced ramp with a sturdy stop pin to prevent the backstop lever from rising beyond a predetermined height. No doubt the mass of the ramp also acts as a weight to further load the backstop lever against slippage.

Just to the right of the backstop pawl is the drive pawl. Which looks rather like a downward turned bird's beak. The sharpened tip of the beak rests in the teeth of the drive wheel close to the backstop. Their closeness is important to avoid backlash between their actions. The drive pawl is hinged at the pin on the right and retained by the wire spring clip. Just below the pin is an adjustable stop screw to prevent the drive lever and its driving pawl from moving too far backwards.

Here, the slave movement has been [temporarily] placed on its side to show the entire drive lever extending from above the locking ramp, at the very top. [Seen at left.] Right down to the armature plate fixed on the bottom end near the core of the large electromagnet. [Seen on the right in this image.] These slave dials must always be used the correct way up or the gravity-aided levers lose their function. The electromagnet is usually placed at the bottom.

A thin spring blade can be seen running parallel with the drive lever. This spring ensures the drive pawl always stays in contact with the drive wheel teeth by applying a gentle downward force on the tip of the rocking "beak."

At each half minute, a brief electrical impulse energises the electromagnet. The drive lever's armature is quickly pulled in against the tension of the drive spring. The drive pawl at the top of the lever moves briefly to the right against its stop screw. As soon as the impulse is over the coiled spring pulls the drive pawl [beak] forwards to step the 120 tooth ratchet wheel forwards by only one tooth. The minute hand, on the same shaft as the ratchet wheel, is thus moved on by half a minute.

Meanwhile, the pin on the drive lever contacts the ramp on the backstop lever and prevents it from lifting high enough to allow free movement of the minute hand during the impulse. The long and heavy hands on the large clock dial might otherwise take control of the slave movement. It is vital that this can never happen or accurate timekeeping will be lost. The minute hand must always point accurately to a full minute. Or midway in between at the half minute. Any less or more will cause doubt in the person reading the time. Clocks are meant to be read at a glance. The advance of the minute hand is so quick that the casual watcher might not even notice it.

The view from the other side of the slave movement showing the large, ratchet-toothed, drive wheel [seen on edge] on the right.

The smaller gears are the motionwork which reduces the minute hand rotation by 12:1 to drive the clock dial's hour hand. These gearwheels are made robust enough to cope with heavy loads as the clock hands are stepped forwards each half minute. They must also act as brakes on the momentum of the heavy clock hands at the end of each sudden step forwards.

The electromagnet can be seen fixed at the bottom of the movement on a sturdy bracket. This bracket completes the magnetic circuit and acts as the electromagnet's keeper during each electrical impulse. Note the robust build of the entire slave movement and the care taken to prevent long term corrosion. The movement would be fitted behind its dial and then possibly forgotten for years unless something went wrong.

The view looking down from the top of the slave movement. With the coiled drive spring nearest the camera.

The view looking down from the top of the slave movement. With the coiled drive spring nearest the camera.The ratchet toothed drive wheel can be seen below the reinforced backstop pawl.

Note the rubber gasket on the flange to protect the movement from moisture when it is installed in its white, protective metal box.

The black plastic block with soldered wires attached is a rectifier. So my theory of an alternative power supply may be true.

Yet another view of the slave movement showing the ratchet toothed, drive wheel. Given an impulse every half minute the drive wheel will rotate once in one hour. [120/2 = 60 minutes.] The drive wheel shaft extends forwards, beyond the white metal case, to a squared arbor which holds the minute hand securely. The pivot for the backstop lever is well seen in the foreground. It is deliberately lowered on the movement backplate to ensure the correct geometry to avoid any chance of backlash or failure to lock in the teeth of the drive wheel. Any error in the movement or locking of the slave will result in the minute hand pointing incorrectly.

Yet another view of the slave movement showing the ratchet toothed, drive wheel. Given an impulse every half minute the drive wheel will rotate once in one hour. [120/2 = 60 minutes.] The drive wheel shaft extends forwards, beyond the white metal case, to a squared arbor which holds the minute hand securely. The pivot for the backstop lever is well seen in the foreground. It is deliberately lowered on the movement backplate to ensure the correct geometry to avoid any chance of backlash or failure to lock in the teeth of the drive wheel. Any error in the movement or locking of the slave will result in the minute hand pointing incorrectly. Here is the front plate of the turret slave movement with the protective metal box in place. The object sticking out of the box [at lower let] is a sprung plunger for advancing the movement in half minute steps. It presses the armature in as if an electrical timing impulse had activated it. The hands on the clock can then be rapidly advanced without affecting the rest of the timekeeping system.

Here is the front plate of the turret slave movement with the protective metal box in place. The object sticking out of the box [at lower let] is a sprung plunger for advancing the movement in half minute steps. It presses the armature in as if an electrical timing impulse had activated it. The hands on the clock can then be rapidly advanced without affecting the rest of the timekeeping system. Note the massive, cylindrical bearing housing to support the heavy clock hands. Any weakness here could cause the hand shafts to sag. Possibly resulting in the hands contacting the face of the dial. Even if this did not stop the normal hand movement it might lead to an ugly scar on the clock dial. The cost of replacement or repair of the dial might be extremely high in an inaccessible situation. Remember that a large clock hand has considerable leverage. A minute amount of slop at the hub could lead to an inch of movement at the tip several feet away. Clock hands are usually counter-balanced to avoid them turning under their own weight.

Here is a close-up of the clock hand, fixing components. The large white boss and bronze cylinder both contain labyrinth seals to stop rain being driven inside the movement by the wind. The hour hand fits on the hour pipe seen just in front of the white boss. The hour pipe is driven by the 12:1 motionwork gearing inside the movement.

While the minute hand slides onto the squared shaft against the bronze cylindrical bush and is locked in place by the screws. The matching squares on the shaft and minute hand ensure no chance of slippage is ever possible. This minute shaft goes right back to the reinforced drive wheel inside the slave movement. The hour pipe acts as a sleeve bearing for the minute shaft and is itself supported by a sleeve bearing in the large white boss.

A clock hand on a public dial indicating the wrong time is far worse than useless. Many people's actions, even lives, could hang on the accurate time shown on the public clock dial. Catching connecting trains is a vital function of such clock dials at railway stations. If the dial is showing the wrong time the public won't know whether to walk leisurely to their platform. Perhaps even visit the platform café if they have time to kill. Or run flat out to catch their train by the skin of their teeth!

Remember that this slave movement came from the end of a long era when public clocks were far more important than now. In the past most people did not possess accurate watches. Nor other more modern devices which could give a really accurate time check. Every slave clock under the control of the master was as accurate as the master clock itself. Usually good to within a couple of seconds a week. Before quartz watches these time systems offered completely unprecedented accuracy to the general public. Only the speaking clock, provided by the telephone company, could match this timekeeping accuracy and had to be paid for each time it was used. It also had to be dialled on a public telephone and the customer then waited for the next spoken time signal and accurate beep. Church clocks and other public clock dials were often minutes adrift unless constantly monitored.

The electrical details have been applied with Dymo tape labels. The electromagnet is separately marked as having a DC resistance of 71.5 Ohms. This is a quite remarkably high figure compared with a normal [small] slave with a resistance of only a couple of Ohms. Such a high figure suggests a very large number of turns of copper wire to obtain a very strong magnetic pull during each very brief, electrical impulse from the master clock.

The movement is expected to operate on 24 Volts DC.

Yet again I am indebted to a fellow enthusiast for sending me these excellent images. I just hope that my use of them repays the kindness in providing them for free public access. Those who wish to share good quality images of Pulsynetic Waiting Train movements, or any other interesting or unusual impulse timekeeping system components, can find my email address at the top of the page.

Click on any image for an enlargement.

*

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)