*

A member of the Antiquarian Horological Society has kindly sent me some images he took on a recent group outing. The AHS Electrical Group were visiting The Cumbria Clock Company in Penrith, Cumbria. [Formerly Cumberland in the north west of England]

The Cumbria Clock Company

Electrical Horology Group - AHS - Antiquarian Horological Society

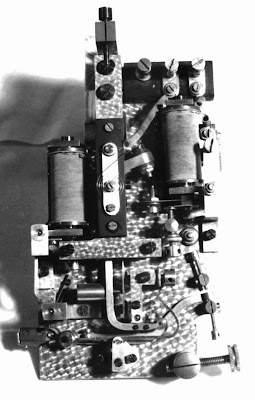

An early WT C40A was on test following restoration by the Cumbria Clock Company. I have done my best to obscure the faces of members of the visiting group to avoid invading their privacy. I you think further work is required please contact me at the email address above.

The earliest WTs [Waiting Train movements] were usually painted black. Though this should not be taken as a fast rule for identifying an early WT. There is far more to it than that and WTs follow a series of changes over the years.

Note how the main frame casting has a gentle curve with a horizontal section before taking a sharp turn downward again. This is in the area just above the large drive electromagnets and is a sure sign of a pre-WW2 movement. Later, post-war movements had a straight, but sloping frame section, just here.

Note how the main frame casting has a gentle curve with a horizontal section before taking a sharp turn downward again. This is in the area just above the large drive electromagnets and is a sure sign of a pre-WW2 movement. Later, post-war movements had a straight, but sloping frame section, just here.The electromagnet coils have visible wire with a thin coating. Later WT coils had a thick wax coating for better protection but which concealed the wire turns. This too gave way, after the war, to a form of bandage for even greater protection from damp and accidental damage.

Interestingly, this early WT has a later contact assembly. This is easily recognizable as having pressed steady bars with gentle bends. Rather than the earlier castings which had sharp bends.

The contact assembly support post is also later. Having a slot for adjustment of the Hipp V-block position relative to the toggle which is fixed to the pendulum rod.

The contact assembly support post is also later. Having a slot for adjustment of the Hipp V-block position relative to the toggle which is fixed to the pendulum rod.However, the contact assembly is made of brass. Not the much later plated steel components of the same form.

In fact all of the minor components are of brass. Which is correct for an early movement. It is quite possible that the original contact assembly was replaced due to wear or damage. Complete replacement being more cost effective than trying to repair the original on-site.

The WT's contacts were probably prone to oiling should the clock keeper [or the vicar] was too enthusiastic with the lubricant. Particularly as the contacts were positioned immediately below the Hipp toggle assembly. Oiling the Hipp toggle on a moving pendulum was apt to become a messy business in unskilled hands! There are always those who think if a little is good then more must be better. It would never occur to them to mop up the excess oil before it ran down onto to the vital electrical contacts.

The WT's contacts were probably prone to oiling should the clock keeper [or the vicar] was too enthusiastic with the lubricant. Particularly as the contacts were positioned immediately below the Hipp toggle assembly. Oiling the Hipp toggle on a moving pendulum was apt to become a messy business in unskilled hands! There are always those who think if a little is good then more must be better. It would never occur to them to mop up the excess oil before it ran down onto to the vital electrical contacts. The pendulum suspension, bearing housing is also in black rather than the later plated finish.

While the armature for the twin, drive electromagnets is a roller rather than the simple hook form of the very earliest WTs. No doubt the Gent's factory staff would apply the latest modifications as each WT was hand built. This would result in a steady but limited change in appearance. Rather than fixed steps falling on clear dates. There would be no desire for originality or even a match of all components if something better had been developed along the way.

While the armature for the twin, drive electromagnets is a roller rather than the simple hook form of the very earliest WTs. No doubt the Gent's factory staff would apply the latest modifications as each WT was hand built. This would result in a steady but limited change in appearance. Rather than fixed steps falling on clear dates. There would be no desire for originality or even a match of all components if something better had been developed along the way.It is difficult to judge but the serial number on the WT relay, pivot plate [bridge?] seems to be 248 or possibly 243? This confirms an earlier date. With very little numbering data to go on I might have suggested early 1930s or late 1920s. Certainly an attractive example of the most common size of C40A WT movement.

This image shows the Hipp toggle has dropped into the V-block and is about to close the drive contacts on the return swing to the right.

The freely swinging, Hipp toggle and its associated V-block were an earlier invention which set the minimum arc of the pendulum when driven by electricity. Whenever the arc of th pendulum fell below the limit set by the arrangement of toggle and V-block the toggle would fall into the V-block. On the return swing of pendulum the V-block is forced downwards, closing the electrical contacts just below.

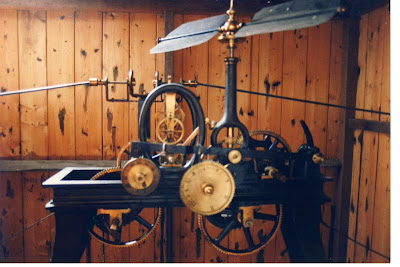

Rear view of the WT movement showing the worm, wormwheel and bevel gear cluster.No attempt has been made to suggest earlier wiring to match the age of the movement. No doubt safety and reliability were considered of greater importance.

All the brass components would have been lacquered in deep gold on the original. These parts look as if they have been lacquered with a clear finish. Deep gold, cold applied lacquer is available. Though the original lacquer would have been applied to pre-heated components. Requiring considerable skill to achieve an even finish without runs or build up on sharp edges.

Yet again I must express my sincere gratitude for being sent these interesting photographs. Without which this blog would be much the poorer for content and interest.

The presence of people in these images is unusual and requires a decision whether they should remain or be digitally painted out. While they do offer a clear suggestion of the scale of items present I am unwilling to publish their images without prior consent. One could argue that by simply placing themselves in a public situation they should expect to appear online. This is obviously a matter of personal preference. Though the difficulty of identifying and then contacting all of those present, for permission to post their images, is all but impossible at a distance. I have therefore chosen to obscure their faces [albeit crudely at times] as a precaution against causing offense. No doubt more sophisticated software would have done a much better job but I do not have such software. PhotoFiltre is free image handling software and has a large range of basic options. Though not the magical "buttons" and controls of expensive software like Photoshop. Even if I could afford such software it would be largely wasted on me and would require a very steep learning curve to make the most of it.

Click on any image for an enlargement.

*

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)

%2Bimp.jpg)