An appeal for WT images on the UK based electric clock forums has produced some excellent WT images. I have reduced the originals slightly for the blog format to avoid long downloads times on slow internet connections. Resizing only takes mere seconds in PhotoFiltre. (a free, image handling, software download which I use a lot)

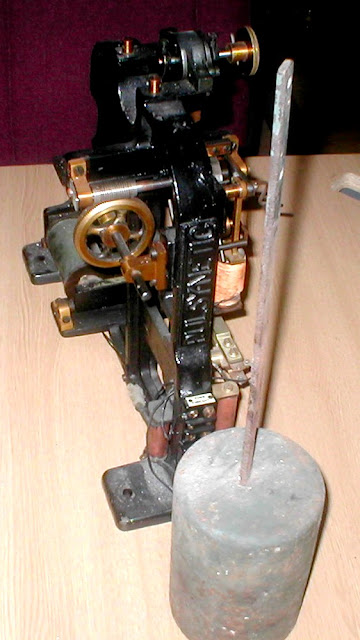

This movement is almost identical to my own. Though with a slightly earlier serial number of 282 against my own 309. Suggesting 1930s manufacture.

In its un-restored condition it looks as if has been painted gloss black. Interestingly, the lower pendulum rod shows that it was probably once the same marine, green-blue as mine. Though it is just possible that the pendulum is a later addition. Early WTs were indeed painted black. It is impossible to tell from this distance which colour is original. Unfortunately I don't have a manufacturer's changeover date to green-blue from the earlier black.

The movement is still covered in polystyrene packaging dust and has obviously just been set up for testing. Hopefully on 20V DC. The owner has stated that the movement is still in unrestored condition. This early movement has the pretty, deep-lacquered, brass details. Later models had plated parts. The sinuous, organic curve on the right of the main casting is indicative of an earlier movement. It looks to be in fine condition but just needs a gentle clean.

Rear view from above showing that the usual bevel gear cluster is absent. This is the second WT I have seen with bevel gears missing.

I hope to try making some bevel gears in my lathe when the workshop finally warms up. I have a Wilding book with instructions on bevel gear cutting.

If you know of anybody who offers to make bevel gears to order, in brass, do get in touch with me. I can then post the information here. Even without bevel gears the WT can still drive the hands of two dials set in direct line with the wormwheel shaft. All it needs is universal couplings and lead-off rods.

A lower view from the rear. The spark quench is visible in the foreground. The large, green, pendulum drive electromagnets are green like my own. These can be nicely restored using odourless lamp oil. Then given them a bath in washing up liquid and hand warm water to neutralise the action of the oil. If the oil is simply left on the protective wax it may eventually dissolve it.

Front close-up. The hand setting crank could be made to look more original with a pepper /salt mill crank with hardwood knob. Sadly the absence of bevel wheels also taken away the maker's, signed, time setting dial. Though a time setting crank is still very useful for rapidly resetting the movement or clock hands to time.This movement still has its original Hipp toggle damper on the extreme right.

Movement end view showing Gents' "Pulsynetic" trade name cast into the main frame. Just below are the terminals for connecting the time series circuit and 20V DC power supply for the drive electromagnets.

The waiting train mechanism in close-up. Note the robust construction for a very long and reliable life. The time circuit relay electromagnet is at lower, centre left. This releases the WT movement from its locked condition on the arrival of the accurate time impulse form the controlling master clock. Without the master clock the timekeeping would be hopeless. Connecting a master clock to a robust and powerful motor pendulum was the death knell for weight-driven turret clocks.

A nice, clear, close-up of the contact assembly and Hipp Toggle and V-block. The absence of lacquer to the contact support bars suggests it has been stripped for some reason. A coat of dark gold, cold brushing lacquer will make a fair job of reproducing the original finish. I ought to do the same to my own WT. Which required a complete new contact assembly to be made from scratch.

-----------------------------------------------------------------

The following images were provided by Paul Strickland:

Only later did I realise that this was the same movement shown above.

The long brown coil at bottom left is presumably a second spark quench, wire wound resistor.

Click on any image for an enlargement. Back click to return to the text.

*

No comments:

Post a Comment